Introduction The cable extruder pushing method is a crucial technique used in cable manufacturing. This article aims to provide a thorough analysis of this method,exploring its principles,benefits,and challenges.

The cable extruder pushing method is a crucial technique used in cable manufacturing. This article aims to provide a thorough analysis of this method,exploring its principles,benefits,and challenges.

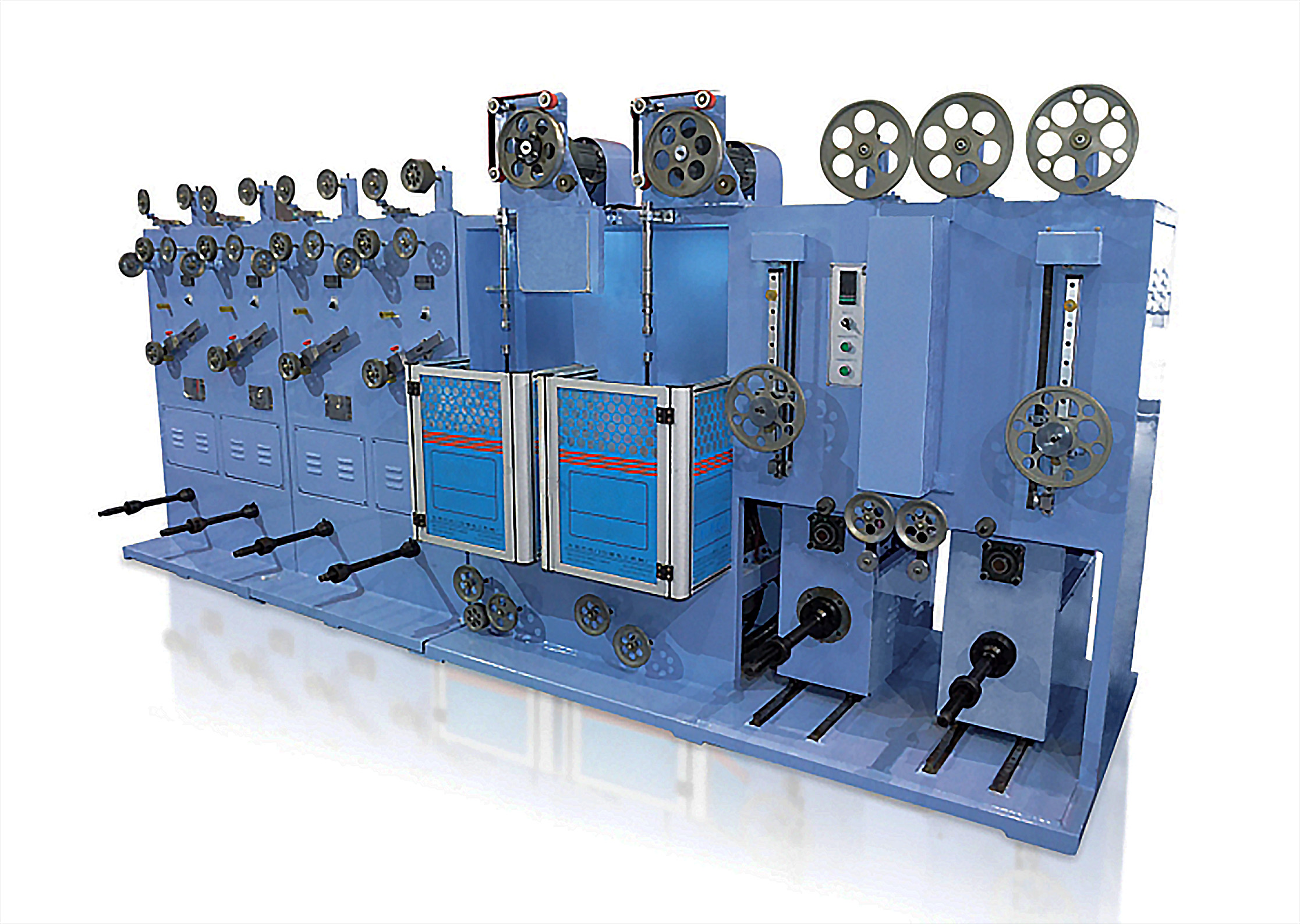

Principles of Cable Extruder Pushing MethodThe cable extruder pushing method involves using an extruder machine to continuously push the cables through a die to create a desired shape and size. This technique relies on the principles of extrusion,which involve the application of pressure and heat to soften the material and force it through a specific aperture.

Benefits of the Cable Extruder Pushing MethodThe cable extruder pushing method offers several benefits for cable manufacturing. Firstly,it allows for efficient and precise control over the cable dimensions,ensuring uniformity and accuracy. This method also enables the production of cables with complex shapes and structures.

Additionally,the cable extruder pushing method ensures a high production rate with minimal waste. The continuous extrusion process minimizes the time required for cable manufacturing and reduces material losses. It also results in enhanced cable quality,as the extrusion process eliminates air pockets and impurities.

Challenges and ConsiderationsDespite its advantages,the cable extruder pushing method requires careful consideration and management. One significant challenge is the selection of appropriate die designs to achieve the desired cable shape and size. The die plays a critical role in determining the final product‘s characteristics,and its design must align with the cable‘s performance requirements.

Another challenge is the control of process parameters such as temperature,pressure,and speed. These parameters must be carefully adjusted to ensure the material‘s proper flow and prevent defects such as air bubbles or inconsistent dimensioning.

Furthermore,the choice of materials is crucial in the cable extruder pushing method. The material‘s characteristics,such as viscosity,elasticity,and thermal properties,need to be considered to achieve optimal extrusion results. Regular maintenance of the extruder machine is also necessary to prevent issues and ensure smooth operations.

ConclusionThe cable extruder pushing method is a valuable technique in the cable manufacturing industry. Its ability to produce precise and complex cable structures,along with its high production efficiency and product quality,makes it a preferred method for many manufacturers. However,it is crucial to address the challenges associated with die design,process parameters control,material selection,and equipment maintenance to maximize the benefits of this method.