Cable extruders are complex machines that require skilled operators to ensure efficient and safe operation. In this article,we will uncover the secrets to mastering the operating skills of a cable extruder. From understanding the crucial components to optimizing productivity,we will provide a comprehensive guide to help operators excel in their roles.

Cable extruders are complex machines that require skilled operators to ensure efficient and safe operation. In this article,we will uncover the secrets to mastering the operating skills of a cable extruder. From understanding the crucial components to optimizing productivity,we will provide a comprehensive guide to help operators excel in their roles.

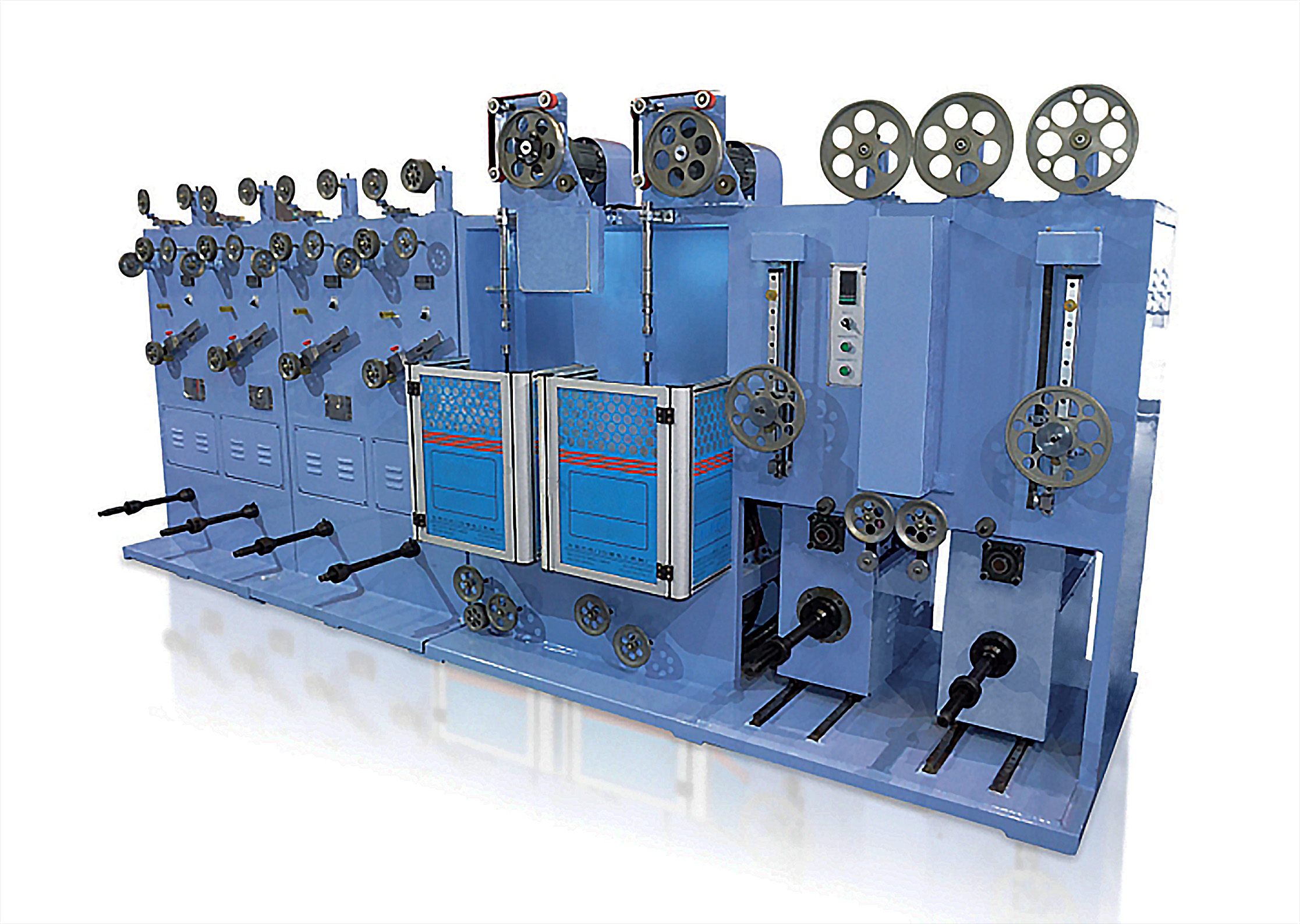

The Components of a Cable ExtruderBefore delving into the operating skills,it is essential to have a clear understanding of the key components of a cable extruder. These include:

- Extrusion Screw: The heart of the extruder,the screw is responsible for melting,mixing,and conveying the material through the extrusion barrel.

- Extrusion Barrel: The barrel encloses the screw and provides the necessary heat and pressure for the extrusion process. It is crucial to maintain consistent temperature and pressure levels to ensure quality output.

- Control Panel: The control panel allows operators to monitor and adjust various parameters such as temperature,speed,and pressure. Familiarizing oneself with the control panel is vital for efficient operation.

Mastering the Operating Skills1. Proper Material HandlingThe first secret to operating a cable extruder successfully is proper material handling. It is essential to ensure that the material feed is consistent and free from contaminants. Additionally,operators should be knowledgeable about the characteristics of different materials to optimize the extrusion process.

2. Understanding Temperature and Pressure ControlTemperature and pressure control are critical factors in cable extrusion. Operators must monitor and adjust these parameters based on the type of material and desired product specifications. Regular calibration and maintenance of temperature and pressure sensors are essential to achieve consistent and high-quality output.

3. Troubleshooting and MaintenanceOperating a cable extruder requires the ability to identify and resolve technical issues. Operators should be familiar with common troubleshooting techniques and have a comprehensive understanding of the machine‘s mechanics. Regular maintenance and cleaning of the machine are vital to prevent breakdowns and ensure optimal performance.

ConclusionMastering the operating skills of a cable extruder is crucial for achieving optimum productivity and output quality. By understanding the components,perfecting material handling,controlling temperature and pressure,and being proficient in troubleshooting and maintenance,operators can enhance their abilities and contribute to the success of the extrusion process.