Introduction The choice of a cable extruder plays a crucial role in determining the quality and efficiency of cable manufacturing. With numerous options available in the market,selecting the most suitable extruder can be a daunting task. This guide aims to provide you with valuable insights on how to choose the right cable extruder for your specific needs.

The choice of a cable extruder plays a crucial role in determining the quality and efficiency of cable manufacturing. With numerous options available in the market,selecting the most suitable extruder can be a daunting task. This guide aims to provide you with valuable insights on how to choose the right cable extruder for your specific needs.

Considerations for Cable Extruder Selection1. Production RequirementsBefore selecting a cable extruder,it is essential to determine your production requirements. Consider factors like the cable size and type,expected output,and desired production speed. This information will help you choose an extruder that aligns with your production goals.

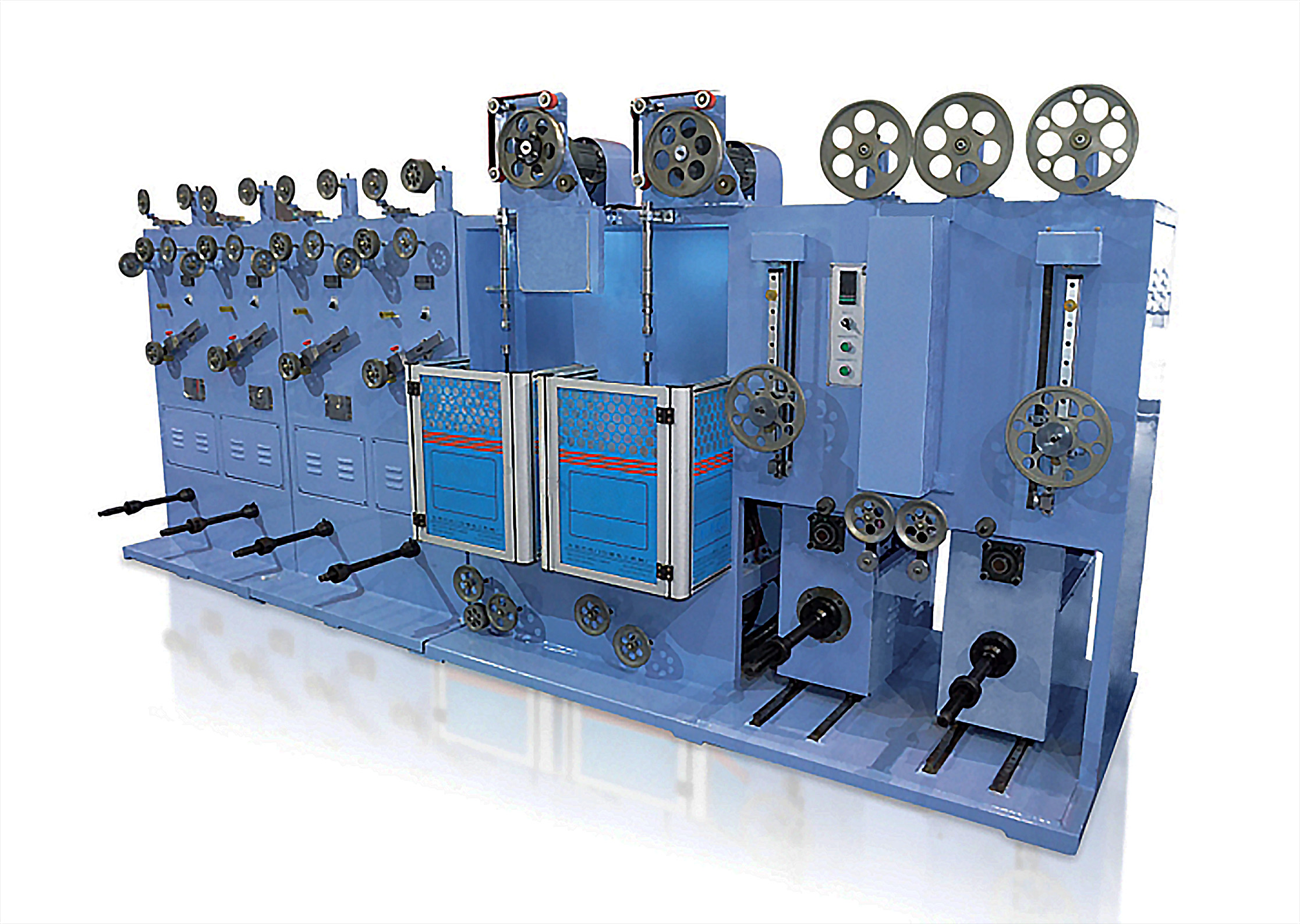

2. Extruder TypeThere are several types of cable extruders available,including single-screw,twin-screw,and multi-layer extruders. Each type has its advantages and is suitable for specific cable manufacturing applications. Evaluate your requirements and consult with experts to determine the appropriate extruder type for your needs.

3. Material CompatibilityEnsure that the extruder you select is compatible with the materials you plan to use in your cable manufacturing. Different extruders are designed for specific materials such as PVC,TPE,or XLPE. Using an extruder that is incompatible with your materials can lead to poor quality and performance issues.

Important Features to Consider1. Screw DesignThe screw design is a critical feature that affects the efficiency and quality of cable extrusion. Consider factors such as the length-diameter ratio,compression ratio,and screw geometry. These features influence the melting and mixing of materials,ensuring uniformity in the cable insulation or jacketing.

2. Heating and Cooling SystemsEfficient heating and cooling systems are vital for achieving consistent and precise cable extrusion. Look for extruders with advanced heating and cooling technologies,such as temperature control zones,adjustable heaters,and water cooling systems. These features help in maintaining optimal processing conditions and reducing downtime.

3. Control SystemsHaving a user-friendly control system is crucial for operating the extruder smoothly and making adjustments as needed. Look for extruders with intuitive interfaces,real-time monitoring capabilities,and features like recipe management. Such control systems enable quick setup,troubleshooting,and seamless integration into your cable production line.

ConclusionChoosing the most suitable cable extruder is a critical decision that impacts the productivity and quality of cable manufacturing. By considering factors like production requirements,extruder type,material compatibility,screw design,heating and cooling systems,and control systems,you can make an informed choice. Take the time to research various options and consult with industry experts to ensure that you select an extruder that aligns with your specific cable production needs.